JOHN COSMAS

Program Manager

home | practice & experience | representative work | portfolio | contact | site map | find

![]()

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||||

|

|

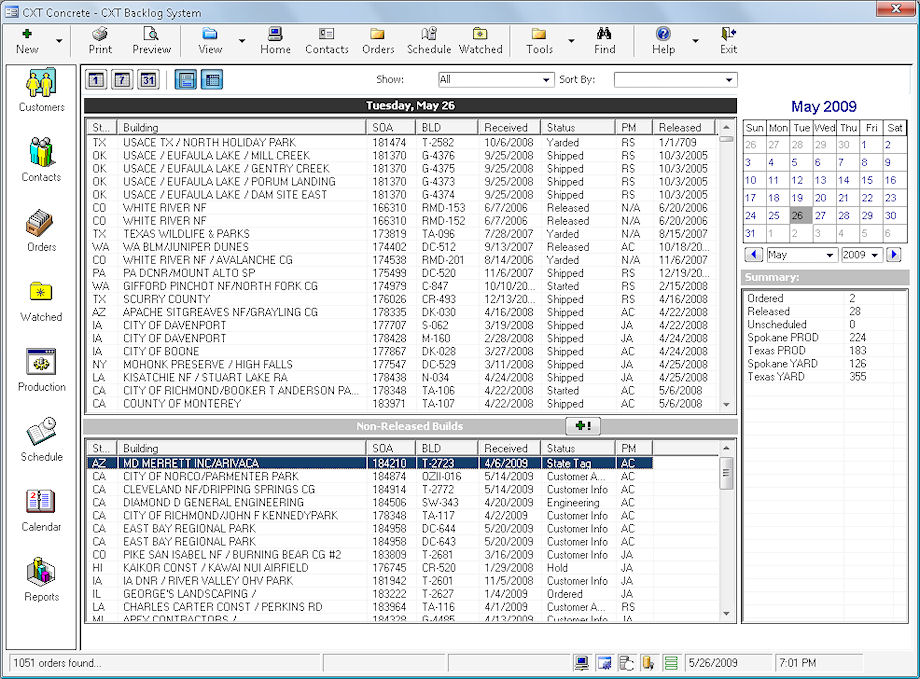

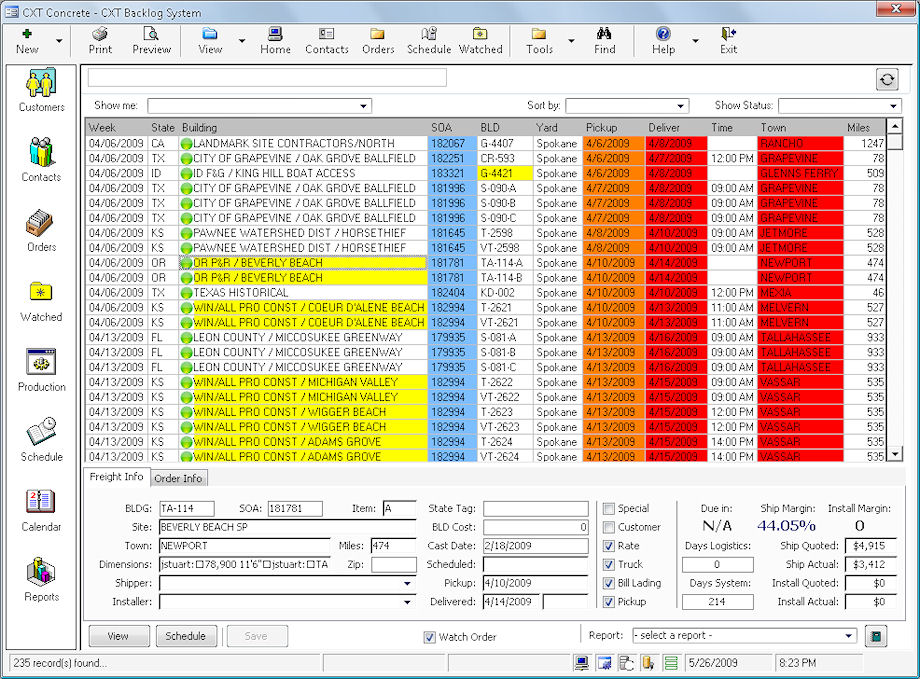

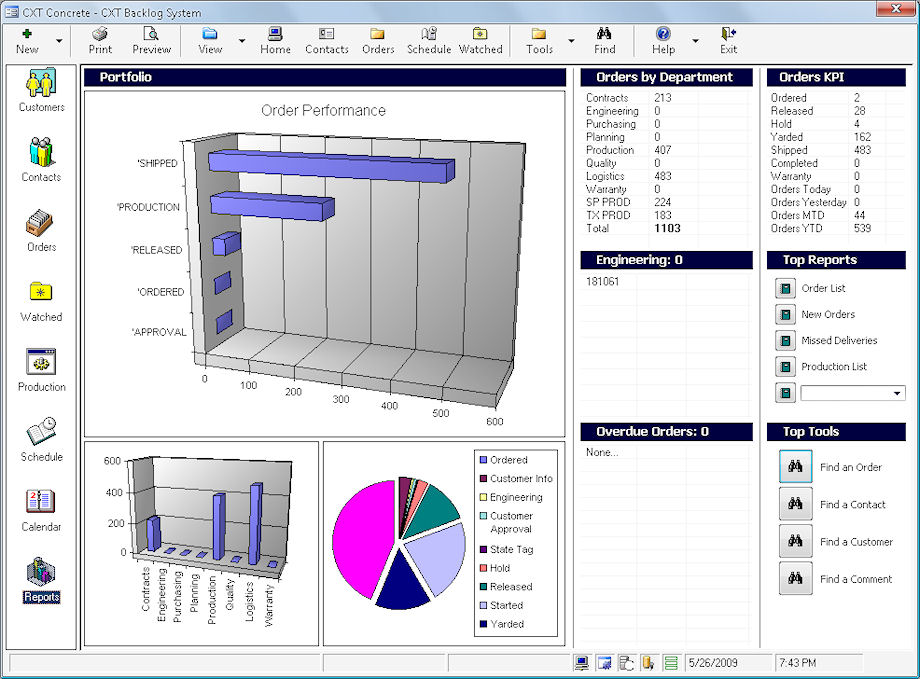

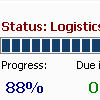

This project was intended to create a new solution that will alleviate the backlog of production activities for the production of pre-fabricated concrete buildings. The core J.D.Edwards system which does not have these capabilities creates an opportunity to alleviate a mission-critical business process. A client-server application designed to operate with a MS Access order management application will comprise of a set of order management, customer management, and scheduling module will serve the needs of production planners to assess, identify, plans and schedule orders while ensuring that participating departments receive their proper status, and have the capability to communicate critical business, regulatory and quality assurance data to ensure the complete delivery of valuable orders. This order management process, it enhanced by the use of user centric data entry forms, detailed process reports, workflow-based processing, coupled by a comprehensive search tool that allows rapid access to the entire collection of order data - including order notes, products and status information. A DASHBOARD model was adopted to help the sales and office personnel to engage operations in a far more responsive manner, by employing status or departmental centric order lists that enhance the way the user conducts business and accomplish tasks on a daily basis.

The system features include:

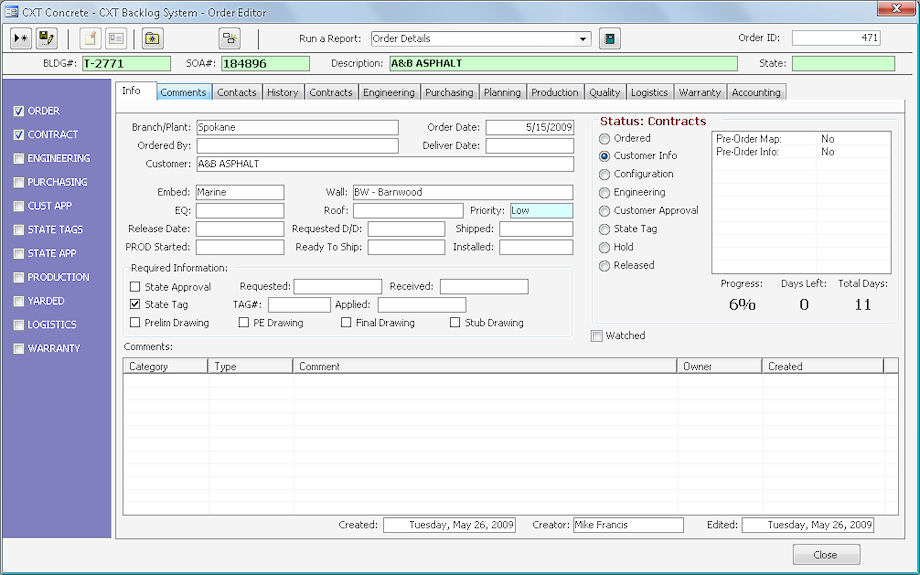

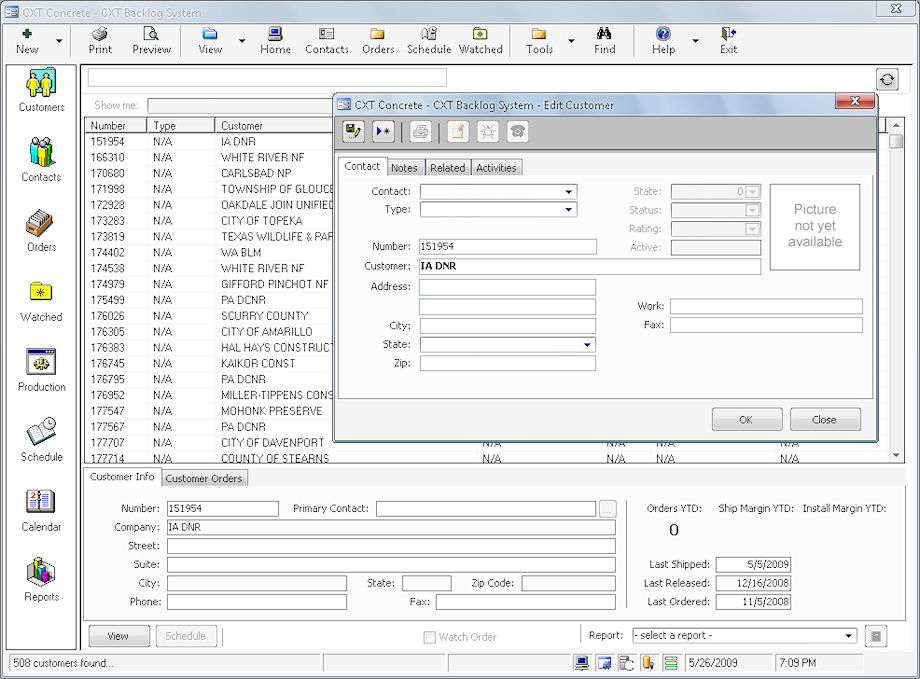

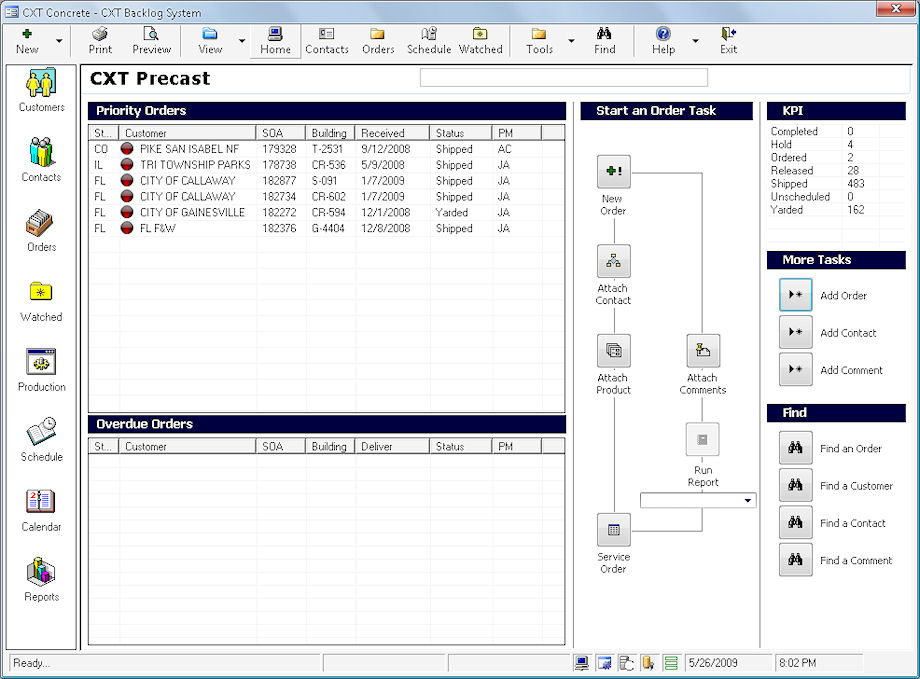

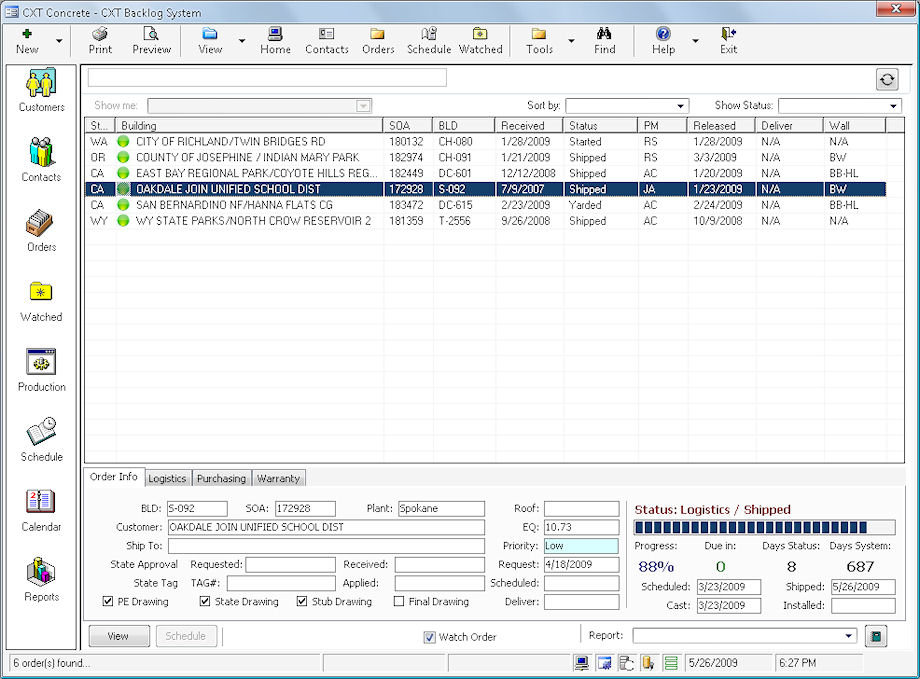

The tabbed interface organizes information so that the user may view order information in an organized fashioned without the added confusion of notes, or historical data. TRANSACTION HISTORY was added to enable users to view the various activities that have occurred on an order. This helps to maintain a progressive view of the evolution through various STATUSes of an order, which offers enhanced service support ensuring timely delivery, and to address product specific REGULATORY requirements. By integrating an OUTLOOK type GUI model, the application adopted an enhanced approach to task, status and workflow driven work processes. The DASHBOARD mechanism embedded into the OUTLOOK model allowed the user to quickly traverse orders, status and customers in a cohesive representation. It is designed to list customer data ordered by status and activity. A CONTACT EDITOR was introduced to help manage contact information resembling the model used in VISTA which is more friendlier and useful. The same approach was adopted in the PROJECT EDITOR which allowed the user to view a project with accompanying product orders in an ordered fashion.

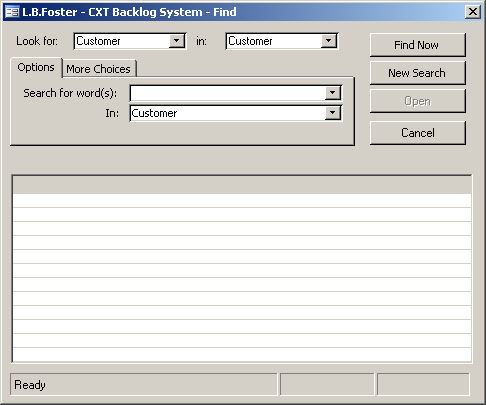

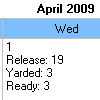

A SCHEDULE EDITOR module was added to help regulate the flow of work on a daily basis, to ensure the completion of each stage of the product assembly, to alleviate production bottlenecks, to improve the allocation of multiple plant resources and to ensure the timely delivery of mission-critical buildings. Coupled with user-centric tasks, dynamically updated STATUS (by involving multiple departments), the overall system ensures that all work is documented, accommodates changes and is properly regulated. To accommodate the large volume of project retrieval, a SEARCH tool was introduced which is designed to search through layers of projects, products, contacts and notes. Enhanced reports were used by reusing the same reports with various rendering were employed to reduce the number of report templates typically required in traditional ACCESS applications, by simply manipulating queries and report controls.

An improved WORKFLOW logic was introduced specifically to ensure as production changes, varying from customized product items, regulatory needs, installation specifications are applied to the order, the order record is routed appropriate through participating departments such as ENGINEERING or LOGISTICS to ensure that the order may be completed successfully. The integration of best-practiced CHANGE CONTROL principles were put into place to alleviate the lack of documentation, and for the eventuality of SIX SIGMA certification.

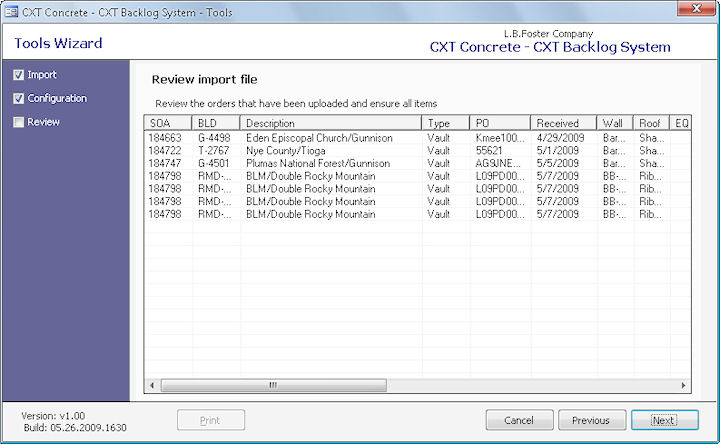

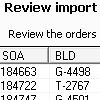

The application is also integrated closely with the J.D.Edwards host database where orders are generated initially, and states are updated to facilitate both enterprise resource planning and sales performance needs. This ensures that all production activities managed through the application communicates critical data to core business systems to reduce the impact overall corporate performance. ETL functions were put into place to streamline the process of data the data exchange and ODBC-direct communication was used to upload status information. An IMPORT WIZARD was also created to allow the rapid integration of external data and link them to individual order records. Data and integration with Lotus Notes, PC-Miler and SalesLogix centralizes many of the operations while focusing the work-load of the user while reducing inefficiencies made possible by disparate systems.

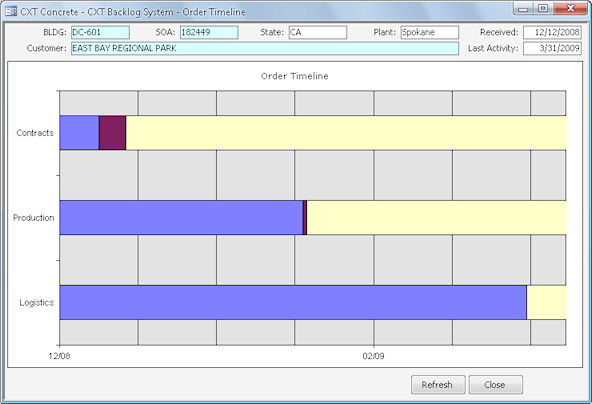

This application represents the first of many operational enhancements that will support the long term needs of the organization that can be developed, deployed and integrated rapidly with ease and while ensuring the highest level of interactivity. Users who used to spend half a day organizing operational data at the beginning of the week will resolve to use this application that decomposes their work load to a week-to-week or day-to-day productivity schedule. The OUTLOOK model combined with SCHEDULING enables managers to view production activity and decompose them along an linear time-frame. A series of automation coding was introduced to help organize, schedule, render and validate ordering to ensure all items are delivered on time, with the highest quality and by overcoming problems that could not be properly documented across a multi-dimensional data structure such as a collection of EXCEL, WORD and NOTES documents. |

|

An N-Tiered design was adopted for this application to enable agent and external tools to service orders and manage workflow processes. The underlying data-driven tables and object enables statuses and workflows to be updated without any code changes to the programming. The WEB SERVICES framework was adopted to enable 3rd-party applications to interact with the application with ease and integrate business rules to retain operational integrity.

The BACKLOG system contained a complete set of order data which is not available in the J.D.Edwards source. Therefore, the customer chose to use the application to create an ORDER quickly and inherit all of its operational data in order to overcome repeated data-entry, and link key elements such as customizations, measurements, quality control load characteristics and accounting information. A NEW ORDER WIZARD was created to alleviate this function and extend all of the order characteristics, while the original order integrity is retained. This time-saving function enabled sales personnel to create orders rapidly using existing characteristics with ease.

Another important feature of the application is the embedded journalizing and logging which enabled uses to track their activities throughout the lifecycle of the order. This also provided them the ability to track changes applied to specific fields and measure specific cycles of activities such as the number of CUSTOMER APPROVAL events and ENGINEERING DRAWING reviews. This was a valuable service for the customer to institute accountability upon internal and external resources such as STATE agencies, SUPPLIERS, 3rd-party ENGINEERING firms and the CUSTOMER (who is accustomed to making changes due to a number of reasons) . Therefore statuses such as HOLD, NON INSTALLs, DELAYs are tagged with specific REASON CODES to enable managers to track reasons for non-delivery or non-performance. REASON CODES enabled managers to report on the problems due to range of real-world issues such as WEATHER, SITE PREPARATION, ORDER CHANGES and SHIPPER DROP-OUTS.

The most useful function of the user JOURNAL is to enabled user to recall any activity throughout a busy and long work day. Two views were created to facilitate this need. The JOURNAL view lists all activities such as RECORD creation, DATA changes such as DATES, NAMES, DIMENSIONS, TEXTURES and so on can be traced. The HISTORY view is confined however to an order level which tracks STATUS changes only. These organized views provides users the ability to get to historical information quickly and search specific records with ease and accuracy. This feature served the requirement for CHANGE CONTROL and re-aligns the PROJECT MANAGEMENT that was disparate throughout the departments

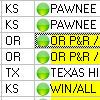

The predecessor of the application were a set of highly customized EXCEL documents that contained color and various character codes that represent a work or status. These work characteristics were integrated directly into the BACKLOG application to ease the transition from an EXCEL platform into a highly functional database which is able to track changes and provide critical reporting. A GRID control was used to serve as the platform in which operational views could be rendered efficiently and provide useful features such as SORTING and FILTERING. This enabled managers to operate with discrete data and make appropriate changes such as SCHEDULED DATES, FREIGHT CONFIRMATION and other critical operations. One of the views was designed exclusively to enable PLANNERS and SCHEDULERS to provision activities quickly because color-coded records provided them visual queues on the status of the record.

A function was built for the WARRANTY department to enable the user to service post-production activities. Problems such as damages, and defects are tracked within orders to enable corporate user to examine the warranty inquiries submitted by a customer for a delivered building. It also enabled them to select a CUSTOMER and view all warranty service orders applied to the selection.

The underlying legacy system which consists of J.D.Edward, Notes and SalesLogix does not provide order or activity based contact management. This application enables users to link a resource such as a SHIPPER, INSTALLER, ENGINEERING firm or SUPPLIER. This application combines all of the contact functions that are fairly limited in its legacy system into a centralized service that provides traceability, accountability and metrics.

Another useful feature of the application is the availability of commenting based on an order status, a REASON CODE or other application entities such as a CONTACT or CUSTOMER. The underlying host systems provided very limited functionality in this area, and the CXT BACKLOG application extends the SEARCH and REPORTING function that is not available elsewhere.

An extensive set of operational, status, historical and financial reporting was put in place to provide user effective views of their progress and work efforts. Traditional detailed, aging reports, error and charts were created to make this application highly functional. Metrics based reporting includes key performance indicators, problems and outages that allows managers to identify and resolve problems quickly, alleviate by a host of useful tools such as TIMELINES, PLOTS and PIE CHARTS. Financial reporting has also been integrated into this application to enable managers to ensure that orders are completed, delivered and serviced accordingly while ensuring its financial integrity.

|

| ||||||||||||||||||||||||||||||

Privacy Policy | Terms of Use

home | practice & experience | representative work | portfolio | contact | site map | find

CXT

Concrete Products

CXT

Concrete Products